You order rosemary essential oil from two suppliers. Same botanical identity, same harvest season, same extraction method. But one batch smells sharp and camphoraceous while the other carries soft, herbaceous notes. Your formulation behaves differently with each batch, and your customers notice.

This isn’t a quality control failure. It’s a chemotype problem. The study of plant chemistry diversity reveals that altitude, soil conditions, and geographic origin fundamentally alter which plant compounds a species produces. Research confirms that β-caryophyllene content can vary from trace amounts to over 41% depending on where a plant grows, creating distinct chemical profiles within the same species.

Botanical names tell you what the plant is. Chemotypes tell you what the plant makes. When you source lavender oil, the species name guarantees nothing about linalool ratios or camphor levels. Harvest timing and terroir drive those numbers, which means your product consistency depends on chemical identity, not Latin taxonomy.

The formulation industry has relied on botanical names for centuries, but that framework breaks down when phytochemical variation determines therapeutic effect and sensory experience. You need more than a plant name to build reliable products.

What is a Plant Chemotype?

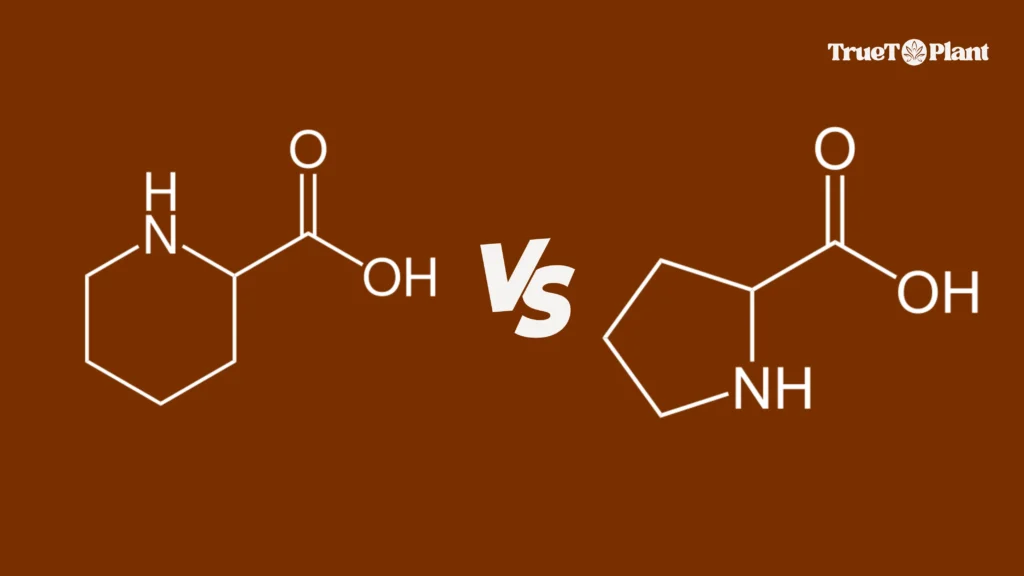

A chemotype represents a plant’s unique chemical fingerprint – the specific mix of compounds it produces based on where and how it grows. When you study plant life across different regions, you discover that the same species can manufacture wildly different phytochemicals depending on environmental pressures.

Think of chemotypes as chemical dialects. Two lavender plants share the same botanical identity, but one grown at high altitude might produce camphor-heavy essential oil while a coastal variant generates linalool-rich profiles. The plant’s DNA stays identical, but soil conditions, harvest timing, and geographic stress triggers reshape which compounds dominate.

This variation isn’t random noise. Research documents β-caryophyllene levels reaching 41.1% in certain chemotypes while remaining barely detectable in others from the same species. These shifts directly impact aroma profiles, therapeutic properties, and how formulations behave in finished products.

Formulators who ignore chemotypes chase consistency with one hand tied behind their backs. You can’t build reliable products when your raw materials swing between chemical profiles batch after batch. Identifying chemotypes through sensory evaluation and analytical testing lets you source strategically, matching specific chemical profiles to your formulation needs rather than gambling on botanical names alone.

Product consistency starts with understanding what your plants actually make, not just what species they belong to.

What is the Study of Plant Chemicals?

Phytochemistry combines botany, organic chemistry, and pharmacology to decode what plants manufacture at the molecular level. When you conduct a study of medicinal plant compounds, you’re analyzing biosynthetic pathways that produce defensive chemicals, structural molecules, and bioactive compounds with therapeutic potential.

This field goes beyond identifying which phytochemicals exist in a botanical. Researchers use platforms like gas chromatography-mass spectrometry and liquid chromatography-mass spectrometry to map complete chemical profiles. You can quantify specific terpenoids, flavonoids, and phenolic compounds, then trace how environmental factors reshape those ratios.

Phytochemical characterization reveals the chemotype story behind each plant population. Studies document how altitude, soil conditions, and harvest timing trigger different biosynthetic responses, creating distinct chemical profiles within identical species. One medicinal plant might produce quinolizidine alkaloids in mountain regions while coastal populations favor triterpenoid saponins.

For formulators, phytochemistry provides the analytical foundation to source strategically. Instead of accepting botanical names as quality guarantees, you can demand specific chemical profiles backed by chromatography data. This precision transforms raw material selection from guesswork into evidence-based sourcing, giving you the consistency needed for reliable product development across every batch.

What Are Chemotypes? Understanding Chemical Variations in Essential Oils

Basil essential oil from one supplier arrives rich in oxygenated sesquiterpenoids, creating a warm, spicy profile. Another batch from the same species smells bright and herbaceous, dominated by monoterpenes. Thyme oil might deliver 40.8% thymol in one harvest, then shift to linalool-heavy compositions from plants grown just miles away. Rosemary presents three distinct faces: cineole chemotypes with eucalyptus-like freshness, camphor-dominant varieties, or verbenone-rich profiles.

These aren’t quality inconsistencies. They’re chemotypes – chemical variations within identical species driven by geographic origin, altitude, and soil conditions. The same botanical identity produces radically different aromatic compounds depending on environmental pressures during growth.

| Species | Chemotype | Dominant Compound | Typical % |

| Thymus vulgaris | Thymol | Thymol | 40.8% |

| Thymus vulgaris | Linalool | Linalool | Variable |

| Rosmarinus officinalis | Cineole | 1,8-Cineole | High |

| Ocimum basilicum | Sesquiterpenoid | Oxygenated sesquiterpenoids | Variable |

Understanding chemotypes transforms how you source materials. When you specify rosemary CT cineole, you’re demanding a specific chemical profile, not just a plant name. Research confirms that chemotypes represent distinct chemical fingerprints within species, making harvest timing and terroir critical factors for product consistency.

Formulators who track chemotypes gain predictable aromatic compounds batch after batch. You’re no longer gambling on botanical names alone – you’re sourcing defined chemical profiles that behave consistently in finished formulations.

Environmental Factors That Shape Plant Chemotypes

Environmental pressures act like control switches for plant chemistry, turning specific biosynthetic pathways on or off. When you grow the same species across different conditions, you’re essentially programming distinct chemical outputs through soil conditions, altitude, and harvest timing.

1. Soil Management Reshapes Terpenoid Production – Research on hemp demonstrates that soil practices fundamentally alter essential oil composition. Cover-cropped soils produced higher total terpene levels compared to conventional tillage across multiple cultivars. The microbial activity, nutrient availability, and soil structure you create directly influence which plant compounds dominate your harvest.

2. Altitude Drives Phytochemical Concentration – Plants at higher elevations face environmental stress that triggers defensive chemistry. Studies on Senna italica show that elevated habitats increase pigment contents and shift flavonoid ratios. Your sourcing altitude determines chemical intensity, with mountain-grown botanicals often delivering more concentrated profiles than lowland populations.

3. Harvest Timing Controls Volatile Preservation – Post-harvest handling matters as much as growing conditions. Cannabis research reveals that water activity below 0.55 causes stomata collapse, releasing 33% more monoterpenes compared to controlled curing methods. Temperature windows between 70-85°F immediately after harvest prevent degradation of volatile compounds that define your plant chemistry diversity.

Formulators who track these three variables gain predictable chemical profiles. You’re sourcing based on environmental data, not hoping botanical names deliver consistency.

How Can Molecules Be Extracted from Plant Samples for Testing Purposes?

Step 1: Select Your Extraction Method Based on Target Compounds – Your choice of extraction technique determines which plant compounds you’ll capture. Solvent-based methods use polar solvents like ethanol for flavonoids or non-polar options like hexane for lipophilic terpenes. Hydrodistillation works well for volatile essential oil components, while supercritical CO2 extraction preserves heat-sensitive molecules without chemical residues. Enzyme-assisted extraction breaks down cell walls for improved yield when you’re targeting specific phytochemicals trapped in rigid plant tissues.

Step 2: Prepare Plant Material for Optimal Molecular Recovery – Fresh or dried plant samples require sectioning to 10-20 μm thickness for comprehensive analysis. Cryo-fixation preserves volatile compounds that degrade at room temperature, particularly important when your terpene profile includes monoterpenes. Grind samples uniformly to increase surface area, ensuring consistent solvent penetration across all botanical tissue types.

Step 3: Conduct Chromatographic Separation for Chemical Profiling – Gas chromatography-mass spectrometry separates volatile compounds like terpenes based on boiling points and molecular weight. UHPLC paired with photodiode array detection captures non-volatile metabolites including alkaloids and phenolic compounds. High-resolution QTOF-MS identifies individual molecules within complex mixtures, generating complete chemical profiles that reveal chemotype identity beyond what sensory evaluation alone provides.

Step 4: Quantify Target Molecules Through Lab Testing – Mass spectrometry data converts peak intensities into concentration values for each compound. You’ll identify dominant molecules that define chemotype classification – whether that’s 40% limonene in citrus botanicals or specific alkaloid ratios in medicinal plants. This quantification enables batch-to-batch consistency tracking, ensuring your sourcing decisions match formulation requirements rather than relying on botanical identity alone.

Strategic extraction paired with analytical testing transforms raw plant material into documented chemical profiles. You gain the data needed to source specific chemotypes, predict product consistency, and build formulations around verified molecular compositions rather than hoping harvest timing and soil conditions deliver what you need.

Building a Formulation Guide: Selecting Chemotypes for Product Consistency

1. Define Your Target Chemical Profile First – Start by specifying which phytochemicals drive your formulation’s performance. If you’re building a calming botanical blend, you need defined linalool percentages, not just “lavender oil.” Document acceptable ranges for each dominant compound before sourcing begins. This reverses traditional procurement where botanical identity comes first and chemistry gets discovered later.

2. Request Batch-Specific Chromatography Data – Demand GC-FID or GC-MS reports for every lot you consider purchasing. These analytical certificates reveal whether your supplier delivers consistent chemotypes or ships plant chemistry variation disguised as the same product. Compare β-caryophyllene ratios, monoterpene profiles, and oxygenated compound percentages across three consecutive batches to assess supplier reliability.

3. Map Geographic Origin to Chemical Outcomes – Track where your botanicals grow and document how location affects your formulation guide. A Mediterranean thyme chemotype rich in thymol won’t match results from linalool-dominant populations grown in different soil conditions. Build a sourcing map that connects specific regions to predictable chemical profiles, then stick with those origins for product consistency.

4. Establish Sensory Benchmarks Alongside Lab Data – Train your team to recognize aroma profiles that signal correct chemotypes before analytical confirmation. Camphoraceous rosemary smells distinctly different from verbenone-rich variants. Sensory evaluation catches chemotype drift between shipments faster than waiting for lab results, giving you early warning when a study of plant medicine reveals supplier inconsistency.

5. Lock Chemotype Specifications Into Purchase Agreements – Write contracts that specify chemical composition ranges, not just species names. Include penalty clauses for batches that fall outside your documented thresholds. This legal framework protects your formulation integrity when harvest timing or environmental factors shift your supplier’s output mid-season.

Case Study: When Chemotype Misidentification Breaks a Formula

A formulation team developed eucalyptus-based antimicrobial products using standardized lab testing that showed excellent inhibition against target bacteria. When they scaled to commercial production, efficacy dropped by over 60%. The culprit wasn’t contamination or processing errors – it was chemotype misidentification.

Research on eucalyptus hybrids revealed that different chemotypes within the same species delivered wildly different antimicrobial performance. One hybrid chemotype achieved potent bacterial inhibition at 1:100 dilution while parent chemotypes required significantly higher concentrations. The team had sourced based on botanical identity alone, assuming consistent essential oil composition across suppliers. When harvest timing and geographic origin shifted between batches, the chemical profile changed completely.

The same pattern appears in antifungal formulations where nanoemulsion stability collapses during storage. Studies document how pH shifts, volatile compound dissipation, and poor food matrix distribution destroy efficacy that looked promising in controlled settings. The essential oil chemotype that performed well in initial testing wasn’t the chemotype delivered in production batches.

Formulators avoid this trap by demanding batch-specific chromatography before scaling. Lock your chemical profile requirements into purchase agreements, not just species names. When you predict chemotype plant outcomes across multiple harvests from the same supplier, you catch chemotype drift before it reaches finished products. True To Plant builds this verification into every formulation protocol, ensuring the chemotype you test matches the chemotype you manufacture.

From Plant Complexity to Formulation Precision

The study of plant chemistry reveals a fundamental truth: botanical names guarantee nothing about chemical behavior. When you source essential oil by species alone, you’re ignoring the environmental variables that actually determine product performance. Altitude, soil conditions, and harvest timing create distinct chemotypes within identical species, each delivering different phytochemical profiles that reshape how your formulations behave.

Regulatory frameworks increasingly demand chemotype-specific labeling, particularly for products making therapeutic claims. Cost-benefit analysis shows that investing in chromatography verification upfront prevents expensive reformulation cycles when suppliers shift chemotypes mid-contract. Sensory evaluation provides practical quality control between lab tests, letting you catch chemical profile drift before it reaches production.

True To Plant builds this precision into every formulation, treating chemotypes as the foundation for product consistency rather than an afterthought. When you respect plant complexity through documented chemical profiles, you gain the predictability needed to scale reliably from prototype to commercial production.