When Tata Chemicals built a digital twin of their carbonation towers, they weren’t thinking about basil. But the logic mirrors what happens inside every leaf: precise chemical conversions, minimal waste, maximum yield. That single percentage point improvement in carbonation efficiency generated $400,000 annually. Plants have been optimizing similar processes for millions of years.

Plant-based formulations operate on principles that extend far beyond food. The same attention to plant secondary metabolites that determines taste and texture in plant based ingredients also informs how we approach local production challenges, supply chain resilience, and product innovation across industries. A chemist solving for nutrient density in plant-based protein faces identical questions to an engineer designing self-healing dental materials inspired by how trees seal wounds with lignified barriers.

The pattern repeats: observe natural systems, decode their chemical logic, translate principles into scalable solutions. Plants don’t just provide ingredients. They model distributed manufacturing, regulatory compliance through consistent biosynthesis, and consumer demand alignment through sensory precision. When you understand how plant chemistry diversity solves complex problems, you gain a design language that works whether you’re formulating beverages or reimagining industrial processes.

What Are Four Positive Benefits of a Plant-Based Diet? Lessons in Simplification and Nutrient Density

Removing options forces precision. When you eliminate animal-derived ingredients, you face the same challenge that drives innovation in any constrained system: deliver complete nutrition with fewer variables. Plant-based nutrition products succeed when formulators treat limitations as design parameters, not obstacles.

1. Enhanced Micronutrient Intake Through Deliberate Selection – Higher adherence to plant-forward nutrition approaches correlates with increased intake of vitamins A, C, E, folate, and minerals like magnesium, selenium, and zinc. This happens because you must intentionally choose nutrient-dense whole-food sources rather than relying on default protein carriers. The American Heart Association notes these patterns reduce cardiovascular disease risk when properly balanced.

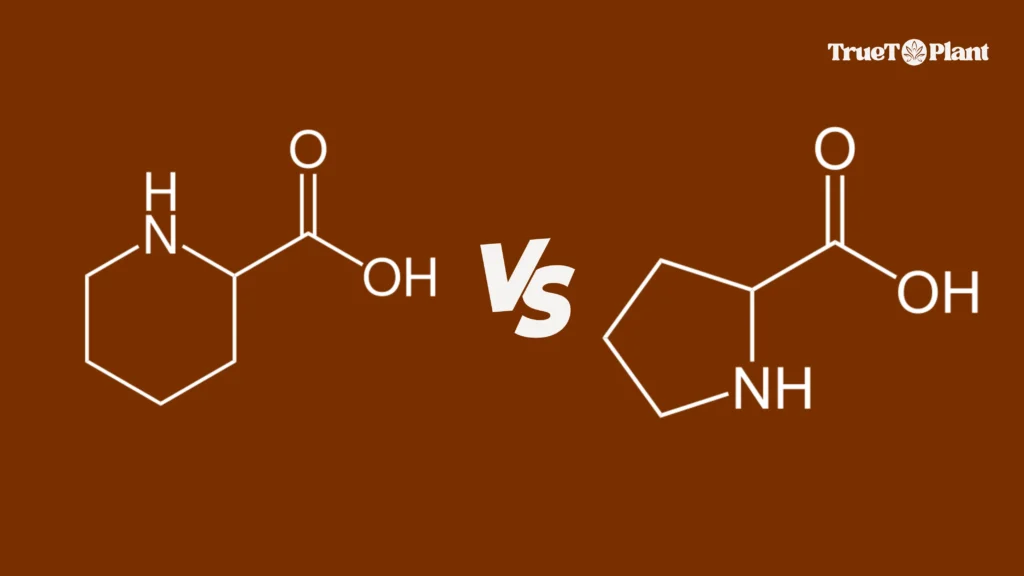

2. Forced Innovation in Protein Quality and Texture – Potato protein demonstrates how constraint breeds solutions. Its favorable amino acid profile and high digestibility make it viable for plant-based protein formulations, but achieving acceptable taste and texture required understanding techno-functional properties at a molecular level. Solving for mouthfeel in meat alternatives demands the same rigor as matching secondary metabolites explained to achieve specific sensory targets.

3. Supply Chain Resilience Through Ingredient Diversity – Dependence on single protein sources creates vulnerability. Plant-based formulations encourage local production by expanding the palette: lentils, chickpeas, hemp, and regional grains as each contribute different functional properties. This diversification mirrors how plants themselves distribute metabolic risk across multiple biosynthetic pathways.

4. Transparency That Drives Regulatory Compliance – Clean label consumer demand pushes formulators toward simpler ingredient lists. When you can’t hide behind complex animal-derived compounds, every component must justify its inclusion. This transparency naturally aligns with regulatory standards while building trust through traceable, whole-food ingredients.

The constraint teaches the lesson: nutrient density emerges from understanding what each ingredient contributes chemically, not just nutritionally.

What Are 4 Ways Plants Can Help the Environment? Supply Chain as Ecosystem Design

Supply chains mirror ecosystems when you design them correctly. Both distribute resources, convert raw materials efficiently, and minimize waste through interconnected processes. Plant-based alternatives demonstrate this principle by forcing manufacturers to rethink sourcing, processing, and distribution as integrated systems rather than linear sequences.

1. Circular Resource Flows From Agricultural Waste – Rosa rugosa petals become anti-aging compounds in cosmetics after initial processing. Elderberry waste transforms into brightening agents. These closed-loop systems capture value at every stage. In the Democratic Republic of the Congo, plantain leaves support Pleurotus mushroom cultivation, generating $4,166.70 profit per hectare from material previously discarded. Plants don’t create waste categories. Neither should your supply chain.

2. Decentralized Production Networks Reduce Transport Impacts – Promoting local production optimizes logistics while cutting greenhouse gas emissions. Transport accounts for less carbon impact than most assume. The real gains come from matching plant-based protein sources to regional growing conditions. Lentils thrive where soybeans struggle. Hemp adapts to marginal land. Distributed manufacturing using plant metabolite formation principles allows brands to source ingredients within tighter geographic radii, improving freshness and traceability.

3. Lower Resource Intensity Across Life Cycles – Plant-based diets require significantly less land, water, and energy than animal-derived equivalents. Life-cycle assessments confirm these reductions extend beyond agriculture into processing and distribution. When you eliminate inefficient feed conversion steps, you compress the entire supply chain. Every kilogram of plant-based protein consumed directly eliminates multiple resource conversion stages.

4. Demand-Responsive Ingredient Diversity – Consumer demand for clean label products pushes formulators toward botanical diversity. This creates market incentives for underutilized crops and regional varieties. True To Plant applies this thinking by treating plants as specialized biomanufacturing facilities. Each species contributes distinct chemical profiles. Diversifying your ingredient base distributes supply risk while supporting agricultural biodiversity. Monocultures fail. Ecosystems persist.

Ecosystem thinking transforms supply chains from cost centers into resilience networks.

Solving the Taste and Texture Problem: Chemical Complexity as Competitive Advantage

Plant-based chicken nuggets fail blind taste tests more often than you’d expect. Consumers detect the difference immediately, and EEG measurements reveal their brains work harder during tasting. The gap isn’t about missing one compound. It’s about missing orchestration across hundreds of volatile molecules, amino acid ratios, and fat crystal networks that animal tissue delivers automatically.

Solving taste and texture in plant-based formulations requires iterative refinement at a molecular level. The Good Food Institute’s sensory playbook documents this process: triangle tests distinguish plant-based nuggets from chicken, flash profiling maps sensory gaps in plant-based milks, and 9-point hedonic scales measure whether meatballs achieve parity. Each cycle narrows the distance between botanical ingredients and consumer expectations.

This iterative approach extends beyond food. True To Plant applies the same logic to complex plant chemistry when building terpene profiles that mirror natural chemotypic expression. Each adjustment tests one variable: adjust linalool concentration, measure sensory shift, refine ratio. Repeat until the blend matches the target plant’s chemical signature.

| Challenge | Traditional Approach | Iterative Solution |

| Taste gaps | Add more flavoring | Map volatile compound ratios, adjust incrementally |

| Texture defects | Change base protein | Test fat crystal networks, moisture binding capacity |

| Consumer rejection | Reformulate completely | Use triangle tests to isolate specific sensory failures |

The competitive advantage emerges from treating formulation as problem-solving rather than recipe-following. Brands that understand nutrient density, regulatory compliance, and supply chain constraints still fail if the product tastes wrong. Product innovation happens when you decode why plant-based protein behaves differently under heat, then systematically close that gap through controlled testing cycles. Consumer demand follows sensory success, not nutritional claims alone.

What Are the Benefits of Plant-Based Products? Market Entry Strategy Through Consumer Demand

Reading market signals correctly determines which plant based ingredients reach shelves and which remain prototypes. Consumer demand doesn’t emerge from nutritional data alone. It builds from sensory satisfaction, convenience, and emotional alignment with health priorities. Seventy-seven percent of consumers rank health as their top food purchase driver, creating clear pathways for brands that decode what “healthy” means in practice versus theory.

Your market entry strategy succeeds when you match formulation precision to observable demand patterns. Fermentful entered European markets by partnering locally rather than building distribution networks from scratch. Their fermented buckwheat kefir ingredient gained credibility through gut health trends and strategic positioning at trade shows where buyers actively sought functional ingredients. Speed mattered less than alignment with existing demand signals.

North America captures forty-two percent of global plant-based protein consumption because infrastructure already supports rapid scaling. Beyond Meat and Impossible Foods didn’t create demand. They responded to patterns showing flexitarian populations growing faster than strictly plant-based demographics. Retailers added dedicated sections, suppliers streamlined ingredient access, and brands compressed time-to-market by working within established distribution channels rather than against them.

Product innovation follows demand, not the reverse. When neuroscience research reveals that cognitive workload during tasting correlates negatively with purchase intent, you know sensory complexity creates friction. Simplify taste and texture before adding nutritional claims. Ensure regulatory compliance supports clean label expectations without sacrificing functionality. Local production becomes viable when regional crops match consumer preferences for traceable, nutrient-dense options.

The lesson: observe where attention concentrates, then build formulations that meet expressed needs with chemical precision. Supply chain resilience and product differentiation emerge naturally when you solve problems consumers already recognize.

What Is an Advantage of Making Plant-Based Products? Affordability Meets Scalability

Standardization unlocks economics that variable inputs can’t match. When Beyond Meat reduced saturated fat by 60% while maintaining 21g protein per serving, they weren’t just improving nutrition. They were creating a repeatable process that manufacturers could scale predictably. Clextral’s Galaxy Texturation Technology now produces fibrous plant-based protein at 400 kg per hour because standardized inputs generate consistent outputs.

Step 1: Lock Down Chemical Profiles Early – Affordability begins with consistency in wild plants transformed into controlled specifications. True To Plant standardizes terpene blends by mapping chemotypic patterns first, then replicating them batch after batch. This eliminates reformulation costs and quality control failures that drain margins when natural variation goes unmanaged.

Step 2: Design for Existing Infrastructure – Plant-based formulations succeed financially when they fit current manufacturing equipment. Nestlé’s AI-optimized development process cut R&D time by 30% by targeting textures achievable with available processing technology. Don’t engineer novel solutions requiring capital investment. Adapt botanical chemistry to proven production lines.

Step 3: Standardize Before Scaling – Ready-to-eat meals fail when taste shifts between production runs. Regulatory compliance costs multiply when formulations drift. The FDA’s January 2025 draft guidance on plant-based food labeling mandates disclosure of plant sources and allergens, making consistency legally essential. Standardized blends reduce testing requirements and accelerate approvals.

Step 4: Treat Local Production as Cost Distribution – Consumer demand for plant-based protein concentrates in regions with established supply chains. North America captures 42% of global consumption because ingredient access and processing capacity already exist. Launching where infrastructure supports your formulation reduces capital needs while maintaining nutrient density standards.

Scalability emerges when you solve chemistry once, then repeat it reliably.

From Regulatory Compliance to Transparent Communication: Building Trust Through Honesty

Regulatory frameworks force precision that marketing departments often avoid. When the FDA evaluates GRAS notices for plant-based sugar alternatives like agave mixed fructans or galacto-oligosaccharides, they scrutinize every claim. That same rigor teaches brands a valuable lesson: transparency builds trust faster than vague wellness promises.

Nestlé’s AI-driven reformulation process reduced labeling errors by over 95% while accelerating inspection speeds by 40%. The improvement wasn’t just operational. Accurate labels meant consumers received exactly what packaging promised, strengthening trust through consistency. Plant-based protein products face identical scrutiny under the FDA’s January 2025 draft guidance, which mandates clear disclosure of plant sources and allergens. Compliance isn’t optional overhead. It’s the foundation for honest communication.

Allulose demonstrates how regulatory approval translates to consumer confidence. This plant-derived rare sugar carries GRAS status and delivers 0.4 calories per gram while tasting like sucrose. The metabolic data matters less than what it represents: verifiable claims backed by regulatory review. When you formulate with ingredients that pass FDA scrutiny, you inherit their credibility.

Regulatory compliance teaches you to say what you mean and prove what you say. That discipline extends beyond ingredient lists into every customer interaction. Brands succeed when legal requirements and marketing messages align completely, eliminating the gap where consumer skepticism grows.

Building Better: The Universal Grammar of Plant-Based Thinking

Plant-based formulations teach five essential lessons: constraints drive precision, ecosystems model resilient systems, molecular complexity creates competitive advantage, demand signals guide entry strategy, and standardization enables scale. These principles extend beyond food into any domain where chemistry meets consumer expectations. When you decode how botanical systems balance nutrient density with sensory precision, you gain frameworks applicable to industrial processes, supply chain design, and product innovation across categories.

The pattern holds whether you’re solving taste and texture gaps in plant-based protein or replicating plant chemistry diversity in wellness formulations. Observe natural systems, extract their chemical logic, translate principles into repeatable processes. Regulatory compliance and consumer demand both reward this approach. True To Plant applies these lessons by treating each chemotype as a manufacturing specification, turning botanical complexity into standardized blends that respect natural expression while delivering consistency. Plants don’t approximate. Neither should your formulations.