The cleaning spray under your sink, the medicine in your cabinet, even the packaging protecting your groceries – they’re all undergoing a quiet transformation. Traditional chemical manufacturing has left us with a legacy problem: hazardous chemicals that persist in our bodies and ecosystems long after we’ve used them. Green chemistry flips this model entirely. Instead of designing substances first and managing their dangers later, this approach builds pollution prevention directly into molecular structure. Real-world impact is already visible. Companies are converting 39 million tons of brewers’ spent grain into commercial flour annually. Manufacturers are replacing petroleum-based plastics with renewable materials sourced from plants. The shift toward safer products and cleaner manufacturing isn’t just reducing environmental impact – it’s proving that waste reduction and chemical safety can coexist with performance and profitability.

What is Green Chemistry in Simple Terms?

The green chemistry definition centers on designing chemical products and processes that eliminate hazardous substances from the start. Rather than creating toxic materials and then controlling their disposal, this field prevents pollution at the molecular level. Paul Anastas and John C. Warner formalized this approach in 1998 through the 12 Principles of Green Chemistry, establishing guidelines that prioritize renewable materials, waste reduction, and chemical safety throughout the entire production cycle.

You see this philosophy in action when pharmaceutical companies design medicines with fewer toxic byproducts or when manufacturers choose plant-derived ingredients over petroleum-based alternatives. The environmental impact extends beyond cleaner manufacturing – it fundamentally changes how chemists approach innovation. Instead of asking “how do we dispose of this safely,” they ask “how do we design safer products that never create the problem.” This shift has driven North America’s green chemicals market to reach $161.87 billion in 2025, with projections climbing to $421.66 billion by 2035 as industries recognize that eco-conscious design delivers both performance and protection.

How Green Chemistry Differs from Traditional Chemistry

Traditional chemistry solves problems after they occur – treating waste, managing hazardous chemicals, and controlling pollution once it’s already created. Green chemistry prevents these issues from the start by designing safer products and processes at the molecular level.

| Aspect | Traditional Chemistry | Green Chemistry |

| Core Philosophy | Control hazards after creation | Prevent pollution at design stage |

| Starting Materials | Petroleum-based feedstocks | Renewable materials from plants |

| Waste Approach | Generate then manage | Waste reduction through atom economy |

| Efficiency Metric | Yield percentage | E-factor (waste per product unit) |

| Safety Focus | Protective equipment and disposal | Inherently safer substances |

The contrast shows up in real metrics. Traditional processes often produce 12 times more waste per unit of product, while cleaner manufacturing approaches using green chemistry principles achieve E-factors as low as 0.28. True To Plant applies this philosophy by extracting secondary metabolites directly from botanical sources rather than synthesizing approximations from petrochemicals. This plant-based design approach delivers chemical safety and environmental impact reduction simultaneously, supported by the natural diversity of plant chemistry found in botanical systems.

What Are the 12 Principles of Green Chemistry For?

The 12 Principles of Green Chemistry serve as a practical blueprint for eliminating hazardous chemicals before they enter production. Developed by Paul Anastas and John Warner in 1998, these guidelines help chemists design safer products while reducing environmental impact from the ground up. Rather than offering vague sustainability goals, each principle addresses specific aspects of chemical design – from selecting renewable materials to maximizing atom economy in reactions.

You can think of them as decision-making checkpoints throughout the development process. When formulating a new substance, chemists reference these principles to choose less toxic solvents, design energy-efficient reactions, and build in degradability. The ACS Green Chemistry Institute actively promotes these standards across industries, demonstrating how pollution prevention and chemical safety integrate into everything from pharmaceutical synthesis to consistent botanical extraction from wild plants. The framework transforms abstract environmental concerns into concrete technical criteria that deliver both ecological protection and manufacturing efficiency.

The 12 Principles of Green Chemistry Explained

- Prevention Over Cleanup – Designing processes that avoid waste entirely beats managing it after creation. Source reduction eliminates the need for costly disposal systems and reduces long-term environmental liability.

- Atom Economy – Maximize how many starting material atoms end up in your final product. High atom economy means fewer byproducts and less waste per unit manufactured.

- Less Hazardous Synthesis – Choose reaction pathways that use and generate substances with minimal toxicity to humans and ecosystems. This principle prioritizes chemical safety throughout the production cycle.

- Designing Safer Products – Engineer substances that perform their intended function while minimizing toxic impact. Safer products protect both users and the environment without compromising effectiveness.

- Safer Solvents and Auxiliaries – Select processing aids that pose minimal risk. When possible, eliminate solvents entirely or choose water-based alternatives over volatile organic compounds.

- Energy Efficiency by Design – Conduct reactions at ambient temperature and pressure whenever feasible. Energy-efficient processes reduce both environmental impact and manufacturing costs.

- Use of Renewable Materials – Source feedstocks from annually renewable plants rather than depleting petroleum reserves. Secondary plant metabolites offer complex chemistry without fossil fuel dependence.

- Reduce Derivatives – Minimize unnecessary modification steps like blocking groups or temporary protections. Fewer derivatization steps mean less waste and shorter production timelines.

- Catalysis – Deploy catalytic reagents in small amounts rather than stoichiometric quantities. Catalysts enable reactions with dramatically reduced material consumption and waste generation.

- Design for Degradation – Build products that break down into harmless substances after use. Degradable materials prevent environmental persistence and long-term ecological accumulation.

- Real-Time Monitoring for Prevention – Install analytical tools that track reactions as they occur. Real-time monitoring allows you to detect and prevent hazardous substance formation before problems escalate.

- Inherently Safer Chemistry – Select substances and physical forms that minimize accident potential. This includes reducing explosion risks, releases, and fire hazards through thoughtful material selection.

These principles work together as an integrated system. When MilliporeSigma redesigned their packaging using bulk formats, they achieved 33-53% waste reduction while cutting unboxing time in half – demonstrating how pollution prevention delivers operational benefits alongside environmental gains.

Plant-based design naturally aligns with multiple principles. Renewable materials from botanical sources eliminate petroleum dependence while often requiring less hazardous processing. True To Plant applies this framework by working directly with plant chemistry rather than synthesizing approximations, respecting the inherent efficiency of natural biosynthesis while delivering traceable, consistent formulations.

Plant-Based Design: The Natural Foundation of Green Chemistry

Green chemistry principles find their most elegant expression in botanical sources. Plants function as sophisticated biomanufacturing facilities, assembling complex molecules through enzymatic pathways that operate at ambient temperature and pressure – exactly what principle six advocates. When you extract compounds directly from renewable materials like leaves, roots, and flowers, you bypass the energy-intensive synthesis required for petroleum-derived alternatives.

This plant-based design approach naturally satisfies multiple green chemistry criteria simultaneously. Botanical feedstocks renew annually. Plant secondary metabolites arrive pre-assembled with structural complexity that would require dozens of synthetic steps to replicate. The pharmaceutical industry increasingly recognizes this efficiency – green drug discovery now emphasizes leveraging biodiversity and reducing hazardous substances by working directly with plant chemistry rather than approximating it in laboratories.

True To Plant demonstrates this philosophy through formulations built around chemotypic expression patterns. Instead of synthetic reconstruction, the approach respects how plants naturally organize their chemical profiles. A cannabis terpene blend mirrors actual plant ratios. A botanical extract preserves the original metabolite relationships. This methodology delivers traceable, renewable materials while eliminating the waste streams associated with multi-step organic synthesis. The result is eco-friendly design that honors biological precision – plants have already optimized these molecules through millions of years of evolutionary refinement.

Examples of Green Chemistry in Everyday Products

Your bathroom cleaner likely contains plant-derived surfactants instead of petroleum-based detergents. That prescription medication may have been synthesized using catalytic processes that generate 90% less waste than older methods. These examples of green chemistry demonstrate how pollution prevention reshapes the products you encounter daily.

Pharmaceutical companies now design drug synthesis pathways that eliminate toxic solvents entirely. MilliporeSigma’s bulk packaging formats for filter products cut waste by 33-53% while reducing unboxing time by half. Their Green Coolers program eliminates 60 metric tons of styrofoam annually – proving that safer products don’t compromise functionality. Surface finishes have moved away from PFAS chemistry toward non-fluorinated alternatives that meet performance standards without persistent environmental contamination.

Packaging materials increasingly sourced from renewable feedstocks rather than fossil fuels. Bioplastics derived from corn starch or sugarcane decompose after use instead of accumulating in landfills. Cleaning formulations replace harsh solvents with water-based systems or citrus extracts. The shift extends beyond consumer goods – industrial applications now favor non-toxic alternatives that reduce worker exposure while maintaining process efficiency.

True To Plant applies these principles by working directly with plants as natural chemists, extracting compounds that arrive pre-assembled through enzymatic pathways. This approach bypasses multi-step synthesis, delivering traceable botanical ingredients that align with waste reduction and chemical safety goals. The environmental impact becomes measurable: fewer hazardous chemicals in production, less energy consumed during manufacturing, and formulations that respect biological precision rather than approximating it through industrial processes.

What is Green Chemistry in Agriculture?

Agriculture has embraced green chemistry through botanical pesticides that replace synthetic chemicals with plant-derived compounds. Neem-based formulations and Bacillus thuringiensis offer biodegradable, target-specific pest control that improves soil health while reducing resistance development. These renewable materials align perfectly with pollution prevention principles by eliminating persistent toxins from farming systems.

The results speak clearly. Rice crops treated with Melia azedarach biopesticide achieved yields of 12 tons per hectare – up from a previous maximum of 1.5 tons. A single application eradicated disease while increasing overall production by 17%. Infection rates dropped to just one plant per 2,000, demonstrating how safer products deliver superior performance without hazardous chemicals.

Infrastructure supporting cleaner manufacturing has expanded rapidly. U.S. livestock farms now operate 400 anaerobic digesters, converting agricultural waste into biogas – a 1,500% increase since 2000. This waste reduction approach has helped 661 water bodies achieve quality improvements by addressing agricultural pollution sources. Green chemistry transforms farming from a chemical-intensive operation into a system that works with biological processes rather than against them.

What is the Goal of Green Chemistry in Drug Design?

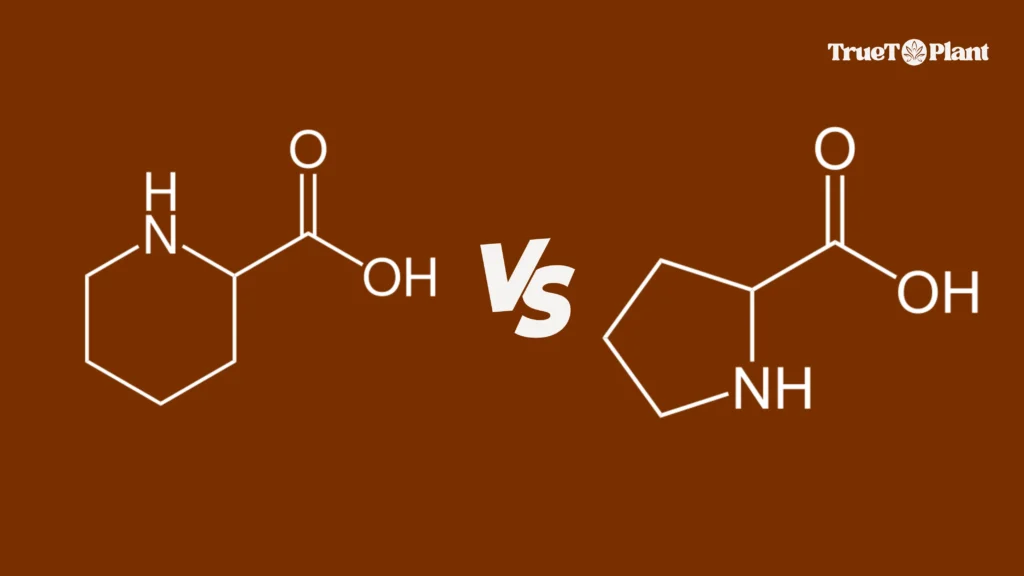

Pharmaceutical development aims to design medicines that heal patients without poisoning ecosystems in the process. Green chemistry transforms drug synthesis by forcing environmental conscious choices from the very first synthetic step. Instead of generating mountains of toxic waste to produce each gram of active pharmaceutical ingredient, chemists now apply principles like atom economy and catalysis to streamline production pathways.

Peptide synthesis demonstrates this shift clearly. Revised solid-phase protocols now integrate pollution prevention directly into laboratory procedures, cutting hazardous chemicals while maintaining research efficiency. Biocatalysis offers another breakthrough – enzymatic reactions produce heterocyclic compounds under mild aqueous conditions, replacing the harsh solvents traditional methods require. One pharmaceutical company achieved 40% lower waste management costs simply by recycling solvents, recovering their investment within two years.

The pharmaceutical solvent market grows 5.04% annually, making waste reduction increasingly urgent. Cleaner manufacturing doesn’t just protect the environment – it delivers cost savings and worker safety simultaneously.

Benefits of Green Chemistry for Industry and Environment

- Economic Advantages Through Waste Reduction – Companies implementing green chemistry principles achieve measurable cost savings alongside environmental gains. Chemical recycling via methanolysis delivers 31% lower manufacturing costs compared to conventional methods. One pharmaceutical manufacturer recovered their solvent recycling investment within two years while cutting waste management expenses by 40%. These financial benefits prove that cleaner manufacturing strengthens bottom lines rather than compromising them.

- Environmental Protection at the Molecular Level – The benefits of green chemistry extend beyond pollution control to pollution prevention. Adipic acid production using bio-based processes achieves 61% lower greenhouse gas emissions than traditional synthesis. Companies converting waste streams like cheese whey into biodegradable plastics eliminate disposal problems while creating valuable materials. This approach addresses environmental impact before hazardous chemicals enter ecosystems.

- Health and Safety Improvements – Designing safer products protects workers, consumers, and communities simultaneously. Engineered enzymes operating at ambient conditions replace high-temperature, high-pressure processes that require extensive safety infrastructure. Renewable materials from botanical sources reduce exposure to toxic substances throughout supply chains, delivering chemical safety without sacrificing performance or reliability.

Building a Sustainable Chemical Future

Green chemistry redesigns substances and manufacturing processes at the molecular level to prevent pollution rather than manage it afterward. This approach prioritizes renewable materials and safer products through principles that integrate environmental protection directly into chemical structure. The shift from petroleum-based synthesis to plant-derived feedstocks demonstrates how botanical sources function as efficient biomanufacturing systems, delivering complex molecules through ambient-temperature enzymatic pathways that eliminate hazardous waste streams.

The market validates this transformation – global green chemicals reached $146.89 billion in 2024, with projections climbing to $387.97 billion by 2034. Industries increasingly recognize that cleaner manufacturing delivers both ecological benefits and operational efficiency. True To Plant applies this philosophy by extracting secondary metabolites directly from botanical sources, creating formulations that mirror natural chemotypic patterns rather than approximating them through synthetic reconstruction. This plant-based design respects biological precision while providing traceable ingredients for products, research, and education.